ANNOUNCEMENT

QAD Redzone acquires Kavida — our Agents have joined the Champion AI family

Discover how AI agents are reshaping the manufacturing operating model

Hi, I’m Alison!

Share your details, and I’ll give you a call in minutes to see how we can assist.

In the past, scaling a supply chain meant adding more people. More buyers. More planners. More analysts. It worked, until it didn’t.

Today, the cost and complexity of expanding headcount often outpace the value it delivers. Teams max out their capacity, administrative tasks pile up, and critical opportunities slip by.

The truth is, the work has grown faster than the workforce ever can. But that’s no longer a dead end. With the rise of agentic AI, supply chains can now scale output dramatically without increasing headcount.

The shift is simple:

- People focus on judgment, strategy, and relationship-building.

- AI agents handle the repetitive, rules-based, and data-heavy tasks that clog up the day.

Why Traditional Scaling Hits a Wall

Most supply chains run into the same three roadblocks:

Fragmented systems

ERP, email, spreadsheets, and supplier portals don’t align. Time is lost just shifting data around.

Manual overload

Chasing RFQs, parsing PDFs, and rekeying ERP data is repetitive, time-consuming, & error-prone.

Linear scaling costs

Historically, more throughput meant more headcount — an expensive and brittle way to grow.

The result? Teams are busy but not necessarily moving faster, or smarter.

Scaling Without the Overhead

Agentic AI changes the rules. Instead of hiring more people to do more work, you deploy AI agents to automate entire workflows.

Here’s how leading supply chains are making it happen:

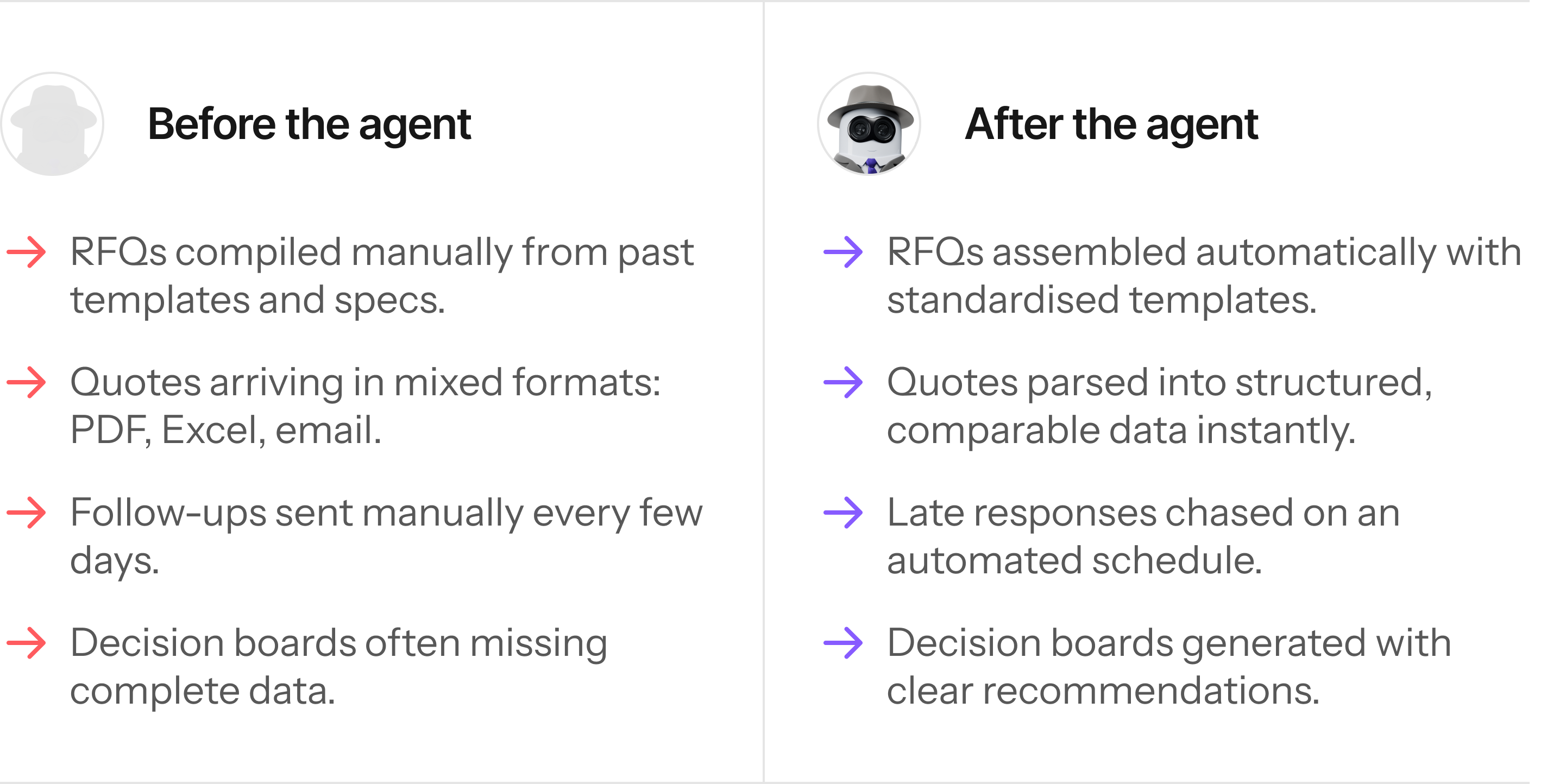

Automate the repetitive

RFQ dispatch, supplier follow-ups, quote parsing, data validation, and bid comparisons are all handled end-to-end by an AI agent.

Work by exception

Instead of monitoring every detail, teams see only what needs their judgment. Everything else runs on autopilot.

Integrate seamlessly

Connect once to your ERP, inbox, and portals. From there, the agent ingests data, runs workflows, and pushes updates with no heavy IT project required.

Break the human capacity ceiling

While people hit natural throughput limits, AI agents can handle hundreds or thousands of transactions in parallel, minus the fatigue and extra cost.

Business Case Study: From Bottleneck to Capacity Multiplier

A global manufacturer wanted to increase sourcing throughput but couldn’t justify expanding their buying team. Their challenge was simple: too many RFQs, too little time, too much manual work.

We deployed Kavida’s RFQ Agent to take over the repetitive tasks.

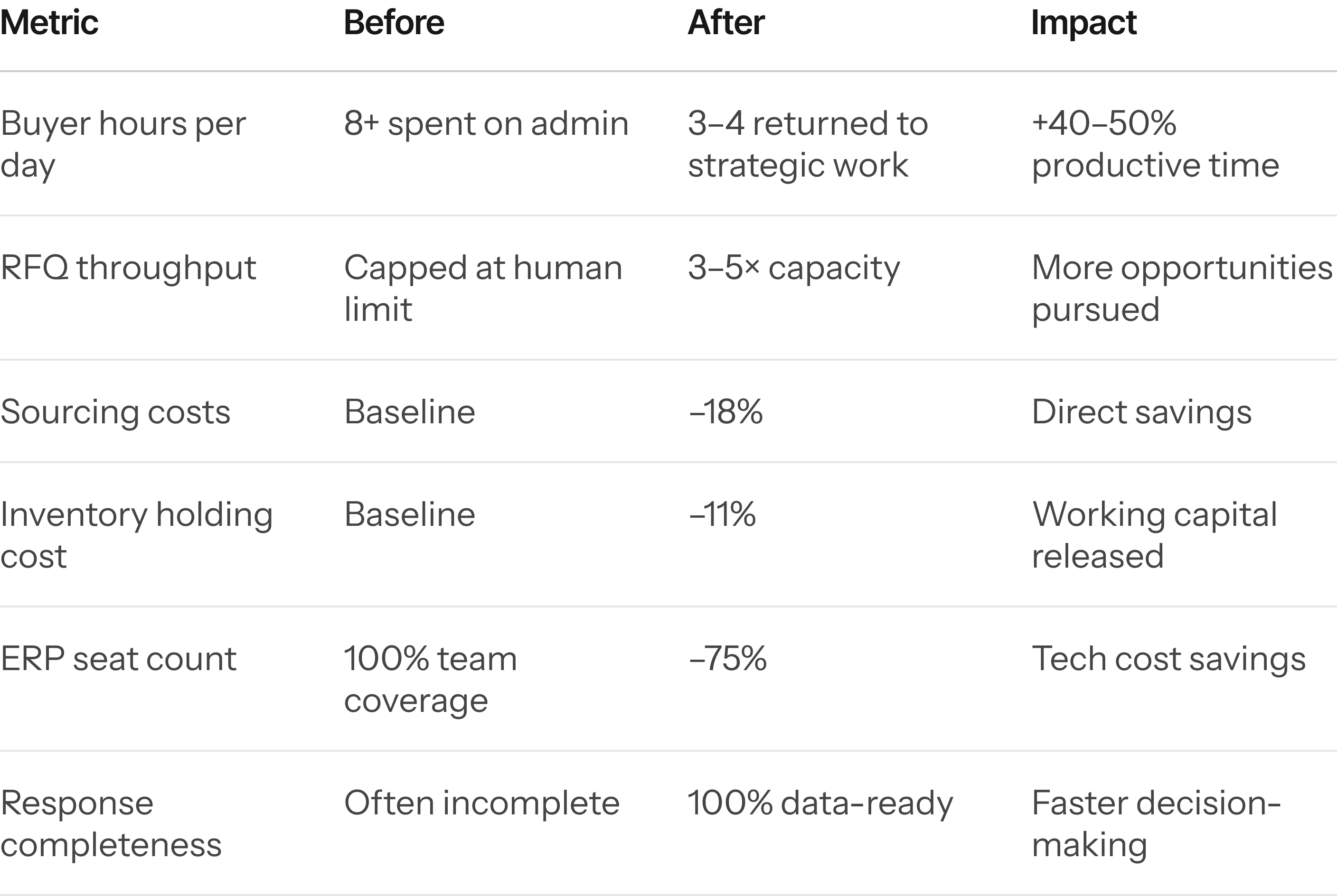

Results at a Glance

The Bottom Line

Scaling your supply chain no longer has to mean scaling your payroll.

By combining human expertise with agentic AI, companies can:

Instantly expand capacity to handle more operations

Cut costs in sourcing and inventory management

Boost decision speed and improve accuracy

Free teams to focus on high-value strategic tasks

Related articles

The Ultimate Guide to Procuring Generative AI for Manufacturers

In the rapidly changing world of technology, From the first assembly lines to the robotics revolution, the manufacturing industry continually strives to find new ways to boost productivity and increase efficiency.

AI Intimacy in Supply Chains – From Agents to Teammates

Imagine this: it’s 8:30 a.m. and your manufacturing team’s first stand-up is with your AI agent. Just like...

Building Resilient Supply Chains in the Age of Disruption

Procurement leaders today need more than just efficient workflows—they need insights that drive smart decision-making. For decision makers...