ANNOUNCEMENT

QAD Redzone acquires Kavida — our Agents have joined the Champion AI family

Discover how AI agents are reshaping the manufacturing operating model

Hi, I’m Alison!

Share your details, and I’ll give you a call in minutes to see how we can assist.

In manufacturing supply chains, an unconfirmed purchase order is a risk multiplier.

When a supplier hasn’t confirmed your requested delivery date, a slip doesn’t just delay the order by a few days — it can delay it by the entire lead time. That’s because without confirmation, you’re effectively starting the clock again when the order is eventually acknowledged.

In a high-volume production environment, those delays ripple through production, logistics, procurement, and customer commitments — creating cascading costs that often total seven figures a year.

The Cascading Cost Structure

Here’s how each cost bucket takes a hit when an unconfirmed order slips:

Production

Without confirmed delivery dates, materials can arrive late enough to stop or slow a line entirely. Production teams must resequence builds, change setups, and work around missing components. This creates:

- Downtime costs (labour and equipment idle).

- Lower throughput, reducing overall output for the period.

- Increased changeovers and inefficiency due to resequencing.

Logistics

Late confirmations often mean late shipments, forcing planners into reactive mode:

- Premium freight or hot-shot deliveries to make up lost time.

- Splitting shipments to keep some production running.

- Higher overall freight cost per unit.

Procurement

Unconfirmed orders that slip may require:

- Emergency buys from alternative suppliers at higher unit cost.

- Lost negotiated pricing on planned orders.

- Damage to supplier relationships from last-minute escalations.

Customer Commitments

Late material often means late finished goods:

- OTIF (On-Time-In-Full) penalties from key customers.

- Chargebacks or lost incentive payments.

- Missed sales revenue if customers cancel or switch to competitors.

- Long-term churn risk if delays become a pattern.

Operations Admin

Every late confirmation creates a wave of internal admin:

- Planners and buyers reworking schedules.

- Customer service teams managing expectations and complaints.

- Management time spent in escalation meetings.

- Additional reporting and firefighting effort.

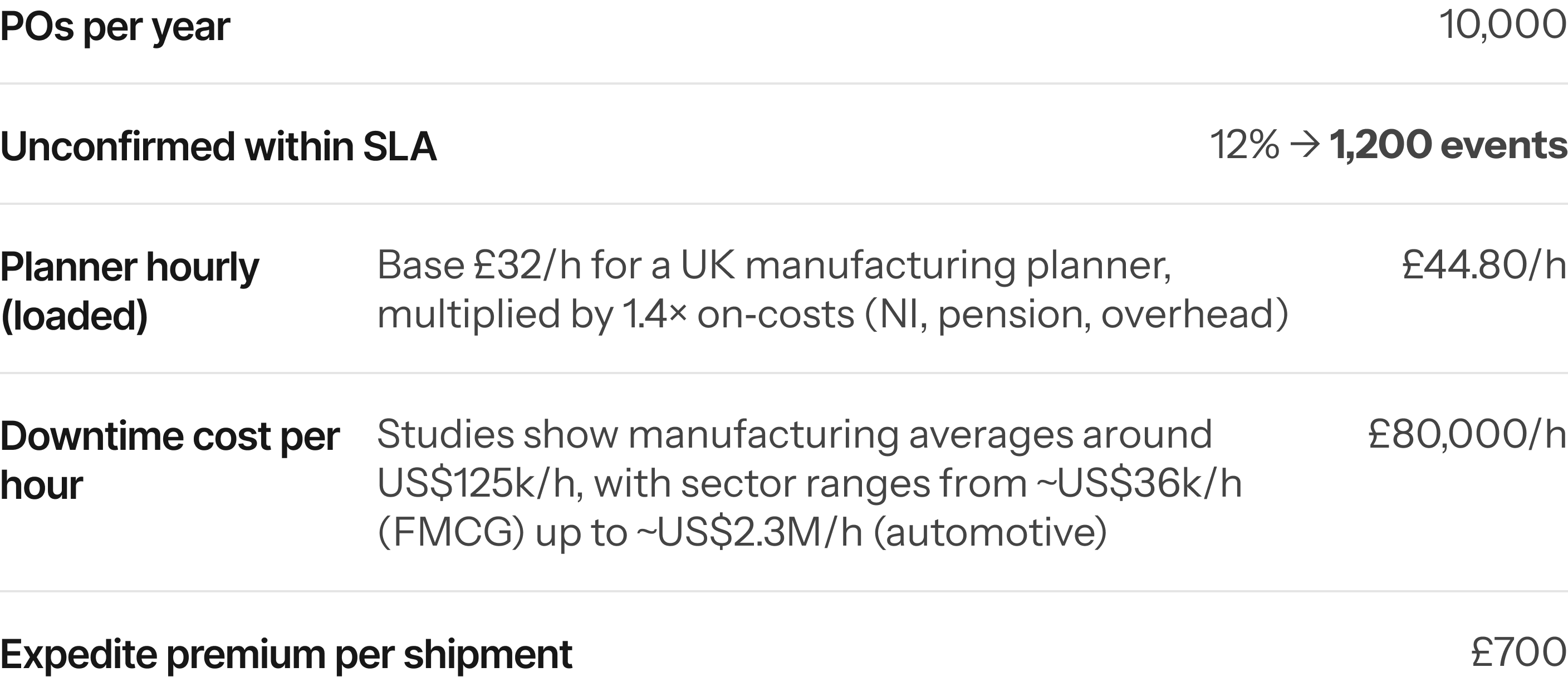

The Million-Pound Math

Even a small percentage of unconfirmed POs can push annual costs into seven figures. Here’s an example model for a mid-sized manufacturer:

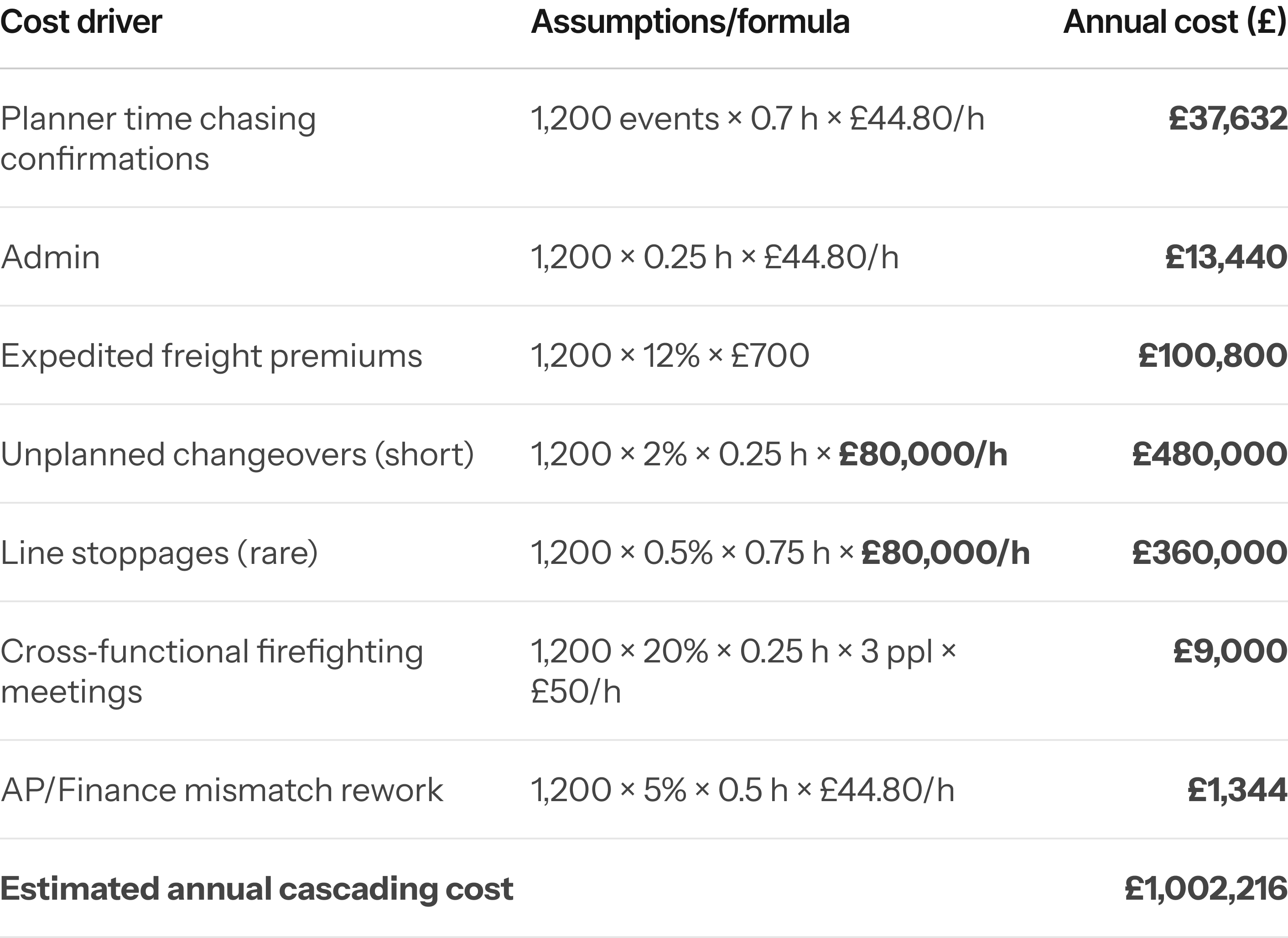

Cascading Cost Breakdown

Even modest assumptions push the total into the million-pound range. And this doesn’t account for lost customer goodwill or opportunity cost.

Why Unconfirmed Orders Happen

Unconfirmed POs are rarely the result of one big failure — they’re usually the by-product of everyday inefficiencies:

- Buyers juggling hundreds of open orders and chasing confirmations manually.

- Supplier replies buried in inboxes, missed or delayed due to time zones.

- No clear SLAs for acknowledgement, and no automated follow-up process.

- Language barriers slowing down communications.

- ERP systems that store dates but don’t proactively flag overdue confirmations.

The result: hundreds of orders that look “in progress” on paper, but in reality, have no fixed delivery date.

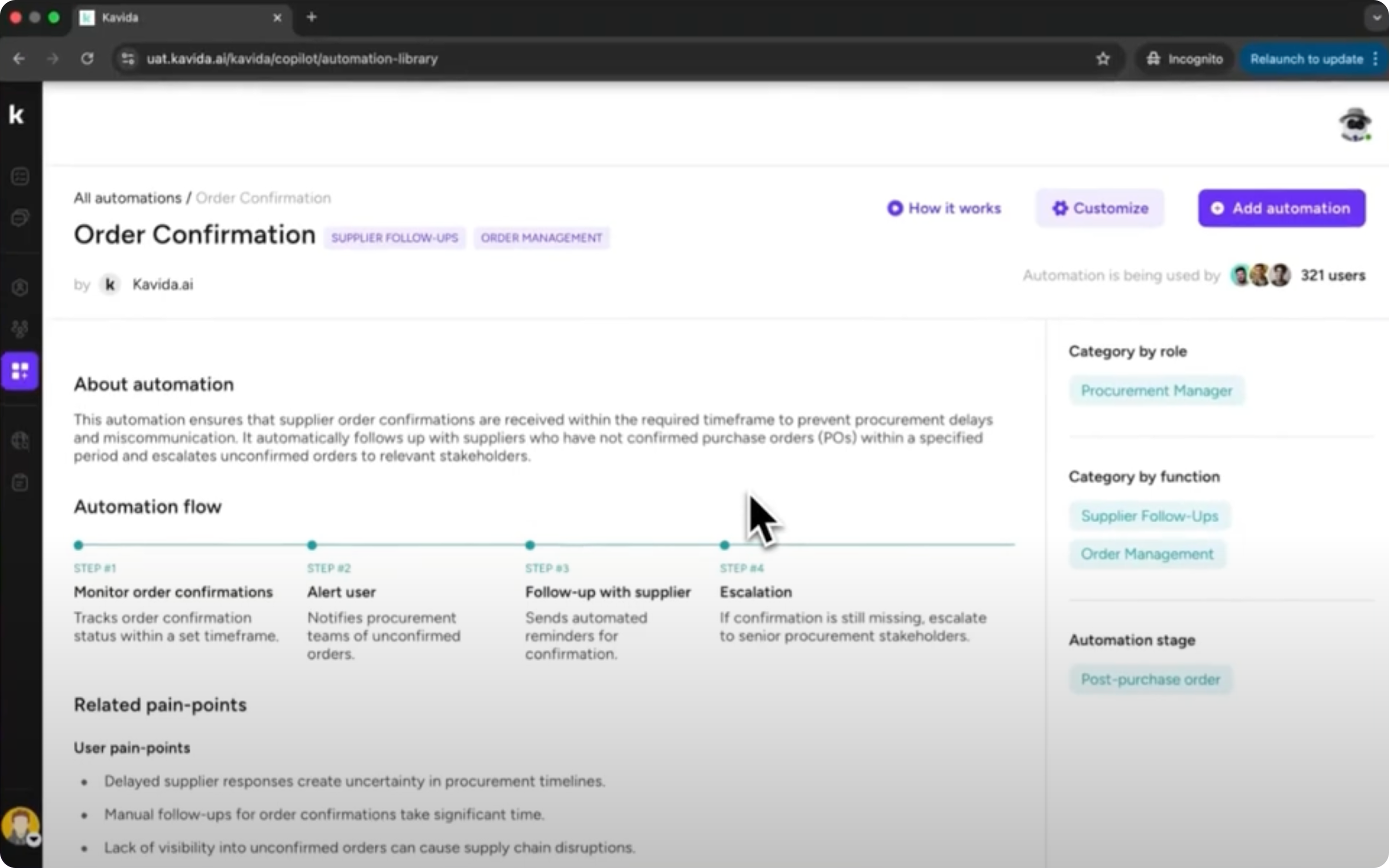

How to Fix It: Automate the Confirmation Loop

Manual chasing will never scale to match the volume and speed required in modern manufacturing. Automation removes the risk of POs falling through the cracks by:

Automated supplier follow-ups once a PO is raised.

Delayed confirmation alerts for orders approaching or past the confirm-by date.

Multilingual support to handle supplier communication in their native language.

ERP auto-updates so confirmed dates are updated automatically.

Unconfirmed orders aren’t small slips — they’re lead-time-sized delays that cascade into production stoppages, premium freight bills, customer penalties, and lost revenue. For many manufacturers, that adds up to over £1M per year in preventable cost.

By automating supplier follow-ups, alerts, and ERP updates — and keeping humans in the loop where it matters — you can turn a slow, reactive process into a fast, governed, measurable one. The result: fewer surprises, lower costs, and a supply chain that runs on confirmation, not assumption.

Related articles

Kavida Joins QAD: Meet Your New Agentic Champions

In manufacturing supply chains, an unconfirmed purchase order is a risk multiplier...

How Agents Unlock Supply Chain Integration After M&A

Mergers and acquisitions promise scale, efficiency, and new market reach — but in supply chains...

Microsoft Copilot Is Not an AI Strategy – How to Think About Horizontal vs Vertical AI Strategy

Enterprises that mistake Microsoft Copilot, or any other horizontal AI layer for a strategy, end up with...