Discover how AI agents are reshaping the manufacturing operating model

Hi, I’m Alison!

Share your details, and I’ll give you a call in minutes to see how we can assist.

The Agentic Transformation in Manufacturing: From Specialised AI Assistants to Intelligent Systems

Table of Contents

ToggleResilience is no longer optional

2020 was the wake-up call. 2021 cemented the lesson. Come 2025, we now know that supply chain disruption is not an anomaly, it’s actually the default state. From COVID-19 shutdowns and geopolitical unrest to semiconductor shortages and extreme weather, the world has entered an era of permanent volatility. The companies that can see through it – are the ones to succeed.

Disruptism marks a new paradigm where overlapping and unpredictable events regularly impact global trade. In this environment, resilience has shifted from being a safety net to a strategic differentiator. Companies that fail to adapt risk more than delays – they jeopardize their revenue, reputation, and long-term viability.

This guide provides a modern framework for building resilient supply chains, offering real-world strategies powered by technologies like Kavida’s agentic platform. Let’s explore how forward-thinking organisations are turning disruption into a competitive advantage.

What exactly do we mean by resilience in supply chains?

Resilience is often misunderstood. It’s not simply about stockpiling inventory or maintaining backup suppliers. True supply chain resilience is the capacity to anticipate, absorb, adapt to, and rapidly recover from disruption. It means proactively sensing potential risks and responding with agility, not reacting after the fact.

In the past, resilience was a tradeoff against efficiency. Today, with advanced technology and real-time data, it can become a performance multiplier. In fact, McKinsey found that companies with resilient supply chains outperform peers by 40% in total shareholder return during periods of disruption.

The anatomy of modern disruption

Why is fragility the default?

Modern supply chains are complex webs spanning continents and thousands of partners. They’re optimised for cost efficiency, not resilience. This makes them vulnerable.

5 characteristics of 2020s-era disruptions:

- Disruptions now occur in constant waves, not as rare events.

- Turbulence spans multiple quarters instead of being short-lived.

- Impacts extend globally across supply chains, not just locally.

- Crises emerge rapidly rather than developing slowly.

- Risks are buried and opaque, no longer easily observed.

Whether it’s a drought in Taiwan disrupting chip production, or geopolitical sanctions interrupting metals flows, disruption today spreads fast, wide, and deep.

Key pillars of a resilient supply chain strategy

The following 5 pillars are the foundation of a modern, future-proof supply chain strategy.

1. Risk assessment and diversification

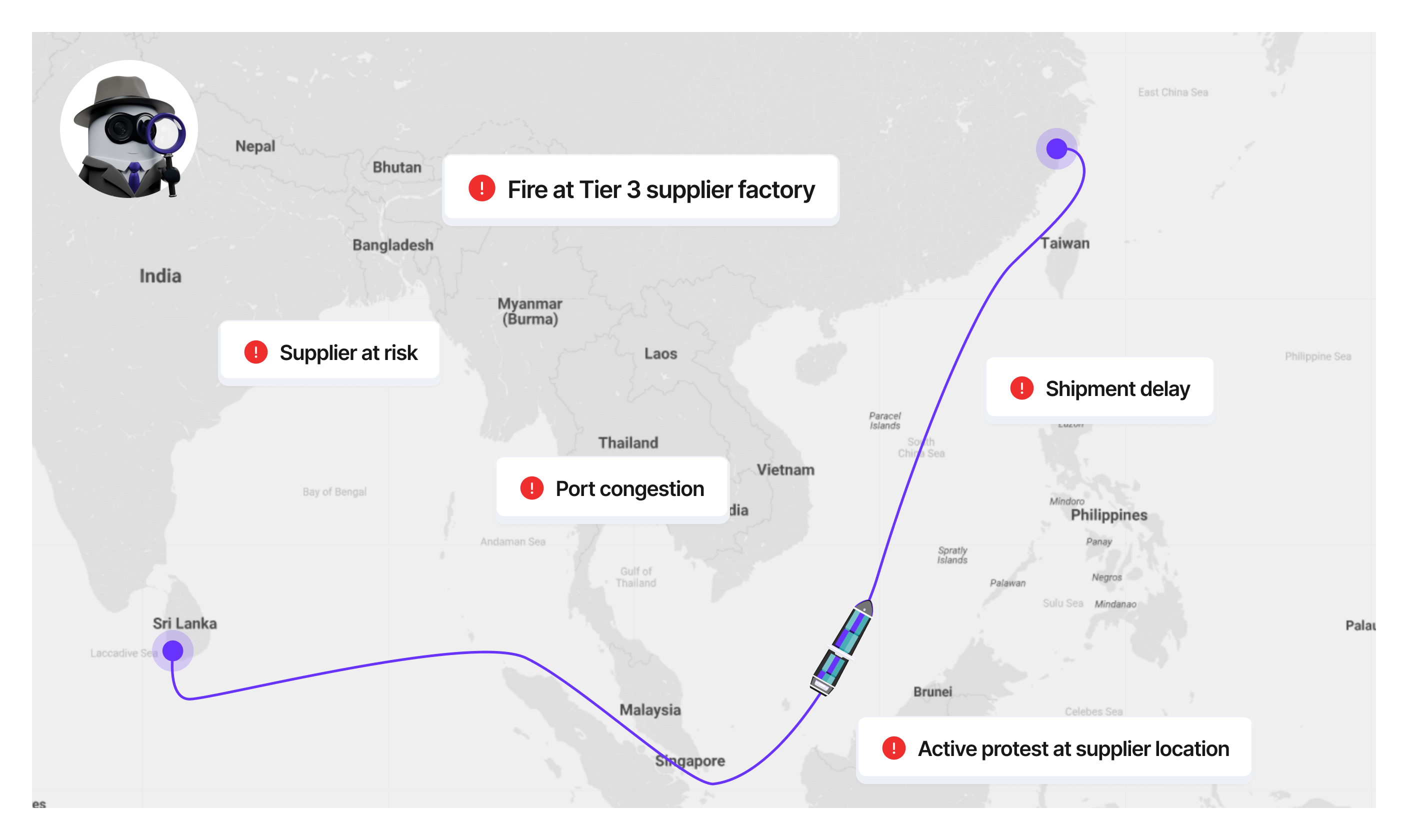

Localised events have global consequences. Risk concentration, whether it’s reliance on a single supplier, country, or logistics route makes companies vulnerable to disruption. To weather storms, organisations must diversify and map their exposure.

- Conduct supply chain vulnerability audits.

- Build dual and multi-sourcing for key SKUs.

- Expand supplier base across diverse geographies.

- Analyse risk not just at tier 1, but tier 2 and 3.

- Use geopolitical, financial, and ESG metrics in supplier evaluations.

Kavida automatically detects concentration risks and flags geographic exposure, giving teams a dynamic heat map of potential weak points

2. Visibility and transparency

You can’t manage what you can’t see. End-to-end visibility empowers teams to respond to disruption in real time and more importantly, to predict it.

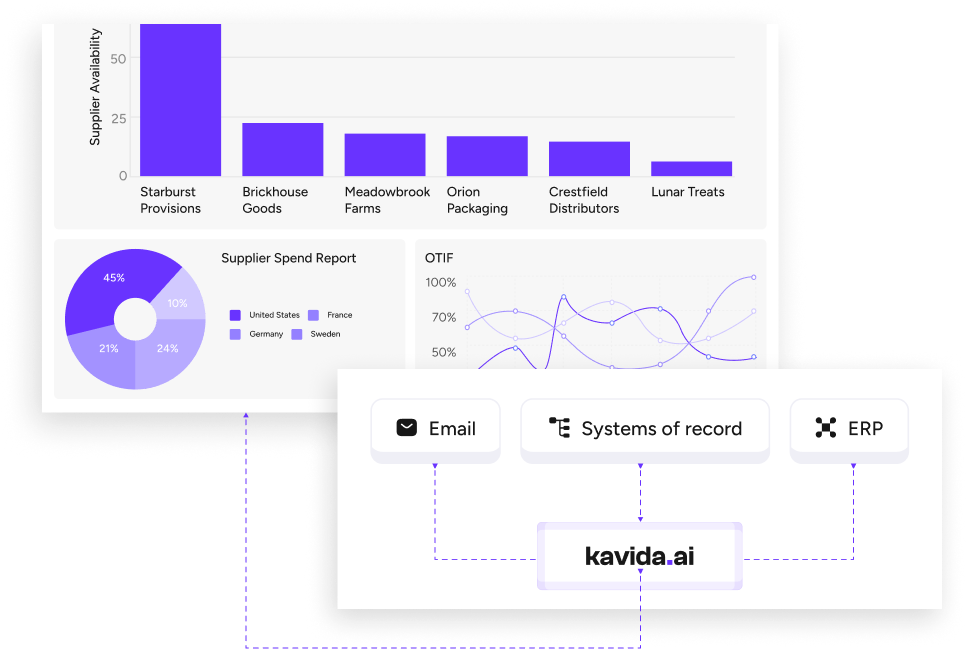

- Integrate supply chain data across ERP, CRM, TMS, WMS platforms.

- Track in-transit shipments with live GPS + port/route intelligence.

- Create real-time dashboards of supplier status, POs, and exceptions.

- Ensure communication and data sharing with critical suppliers.

Kavida automatically detects concentration risks and flags geographic exposure, giving teams a dynamic heat map of potential weak points

3. Collaboration and Control

A siloed operation slows everything down. In disruption, time is everything. You need fast, coordinated response

- Create a cross-functional supply chain control tower for a single source of truth you can rely on.

- Automate coordination between procurement, logistics, and manufacturing.

- Escalate issues intelligently based on revenue impact.

- Maintain audit trails of supplier communication and commitments.

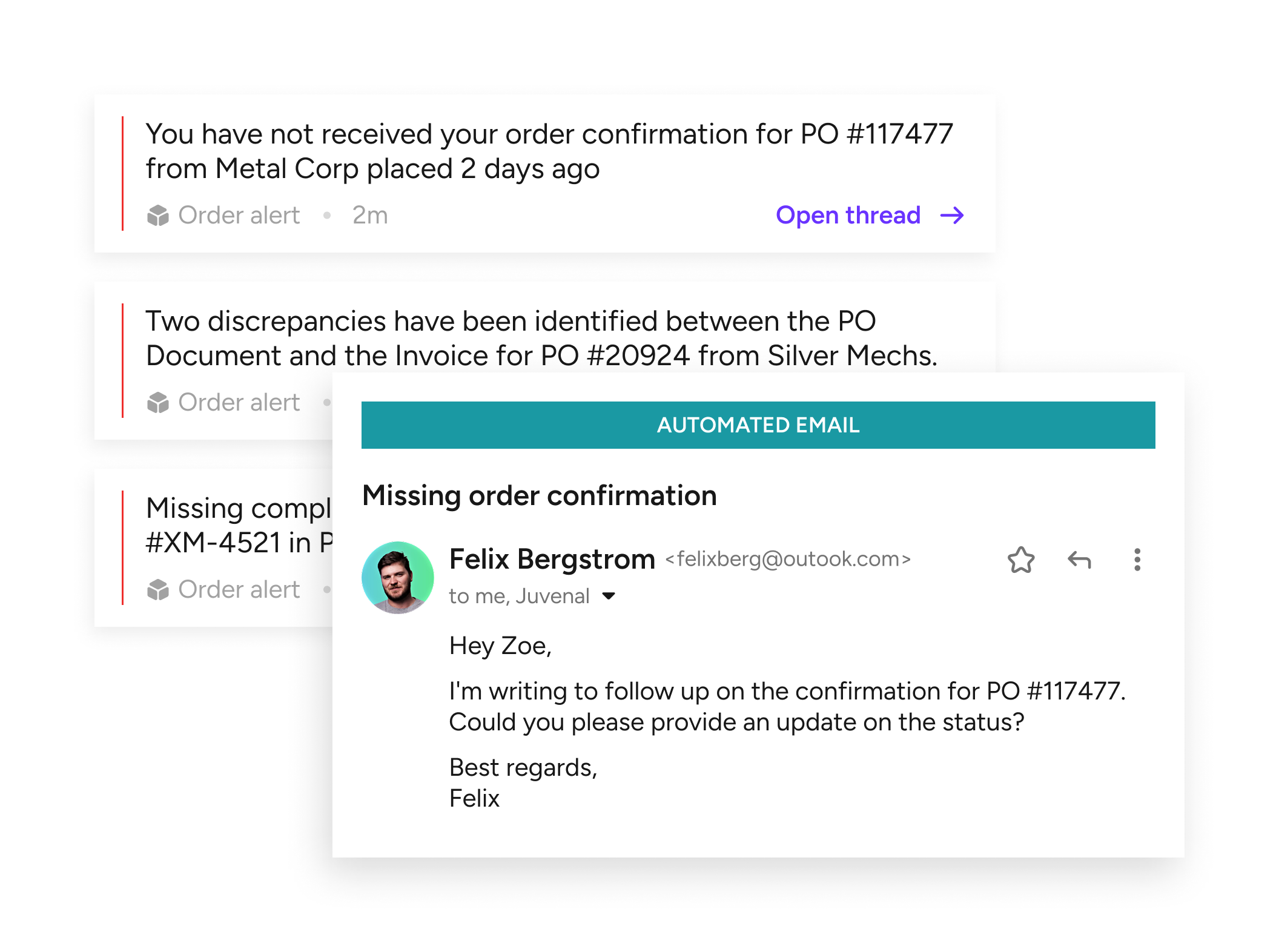

Kavida breaks down traditional silos between procurement tools like ERPs and email threads, follows up autonomously, logs supplier responses, flags high-risk issues, and triggers cross-functional workflows for resolution.

4. Technology and Innovation

Manual processes can’t keep up with the speed and scale of modern disruption. Without automation, analytics, and integration, you’re flying blind.

- Use AI to monitor external signals (weather, sanctions, ESG alerts).

- Automate exception handling and PO confirmations.

- Run simulations for contingency planning and scenario modeling.

- Connect your entire digital stack without re-platforming.

With secure integration into ERP, CRM, WMS, analytics, and more, Kavida layers intelligence without disrupting core systems. SOC2, ISO 27001, and GDPR compliance ensures data safety.

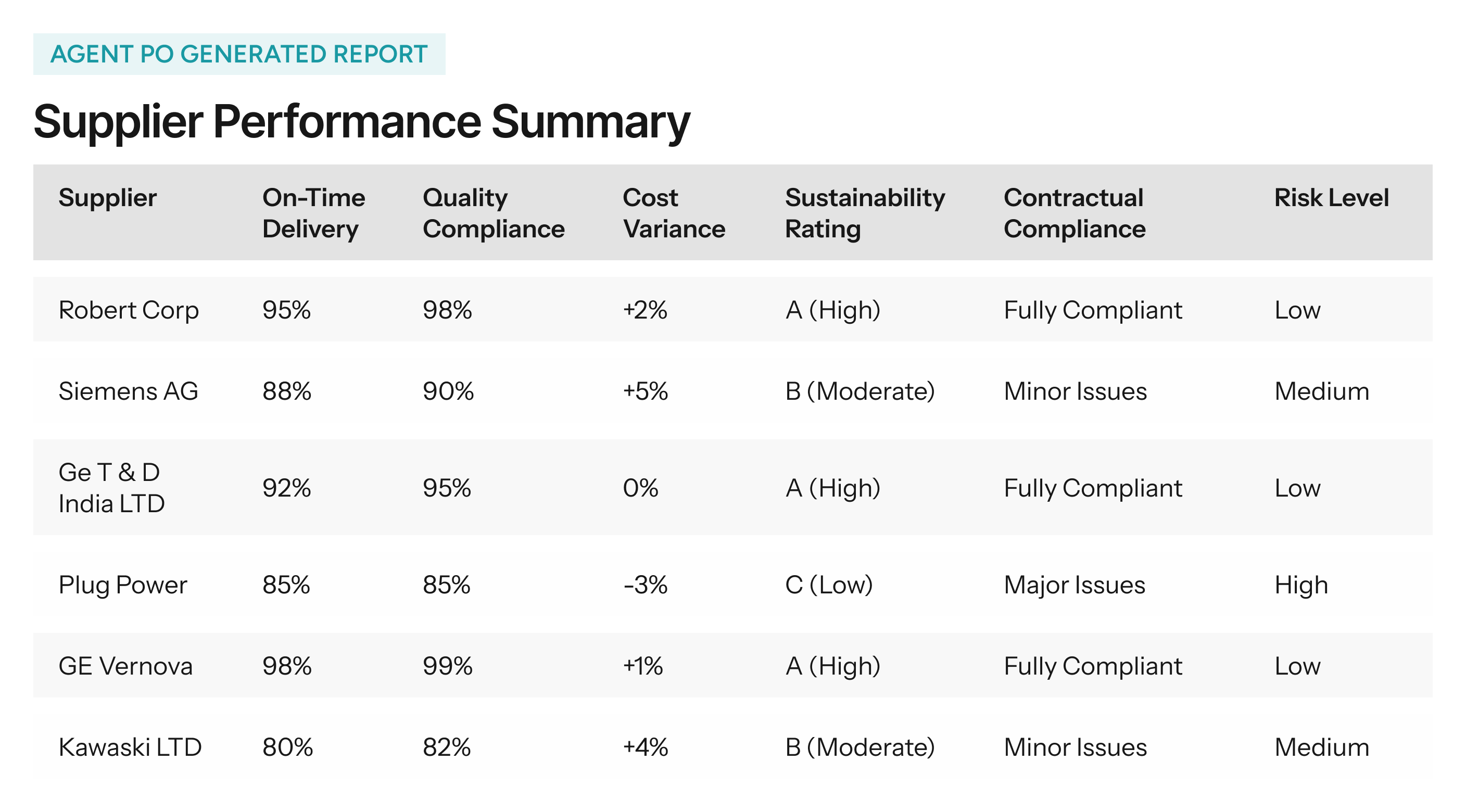

5. Strategic Sourcing

Leaders today discuss how sourcing is no longer just about finding the cheapest option. It’s about building a supplier portfolio that’s aligned with your risk appetite, values, and operational strategy. This sourcing strategy determines your exposure.

- Factor supplier resilience and ESG scores into RFPs.

- Simulate sourcing outcomes under stress.

- Build flexible, performance-based contracts with built-in SLAs.

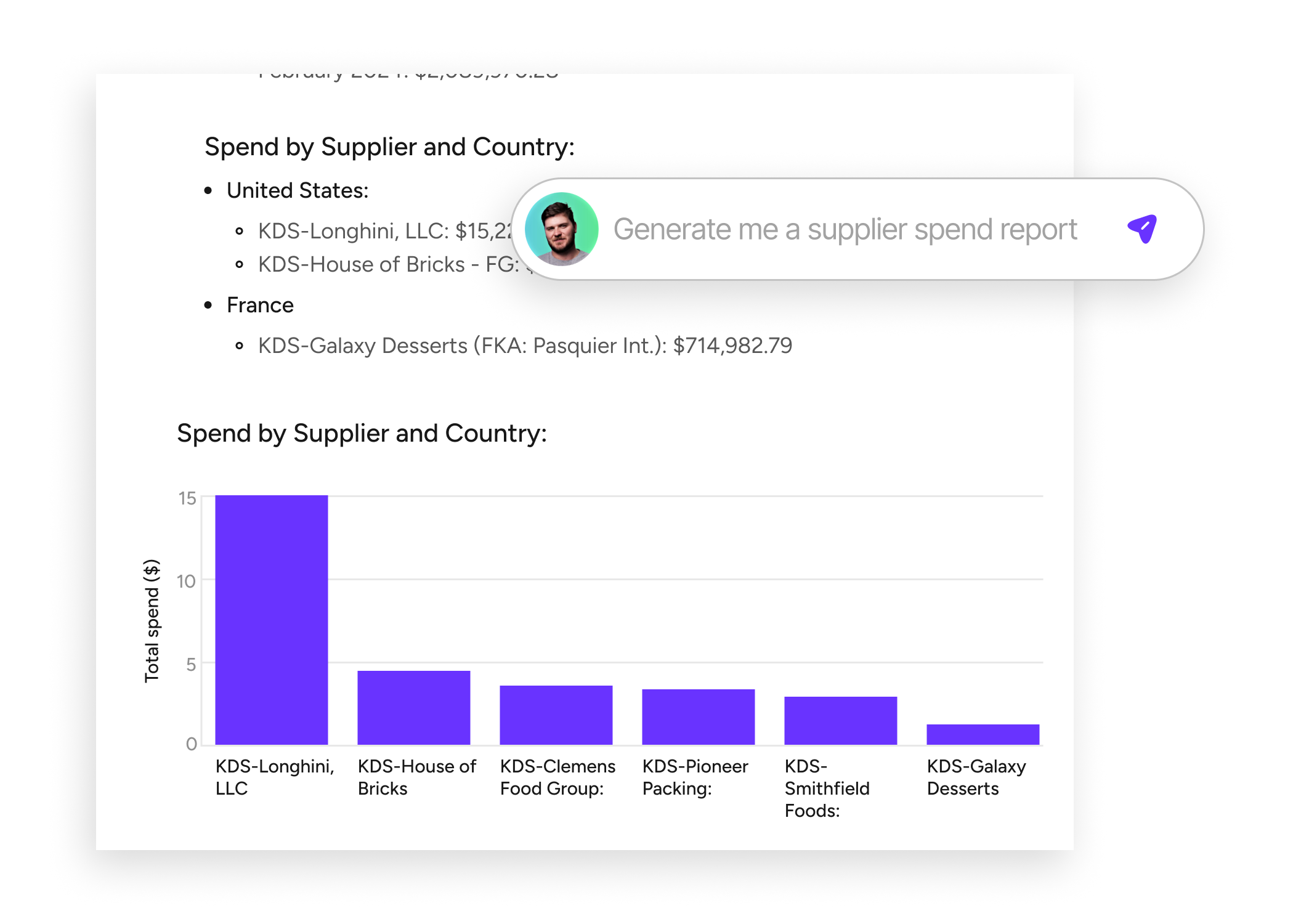

Kavida delivers granular supplier performance analysis, continuously tracking OTIF, responsiveness, and documentation to spotlight risk.

Kavida-powered resilience in action

Here’s how manufacturers are already pulling ahead:

Measuring the ROI of resilience

What happens when you don’t invest in resilience?

Customer churn

67% of customers switch brands after 2 failed deliveries

Stock price hit

Disruptions cause 7-10% valuation drops

Recovery drag

Each day of disruption adds 7-10 days of recovery

Talent burnout

Procurement teams overwhelmed with manual firefighting

Don’t just survive disruption. Surf on it.

Disruptions are here to stay. But they don’t have to be existential threats.

Kavida empowers you to:

- Predict disruption before it hits.

- Automate and scale your operational response.

- Align procurement, logistics, and finance around a single source of truth.

Ready to see how resilient your supply chain really can be? Book a demo today, see it in action

The Agentic Transformation in Manufacturing: From Specialised AI Assistants to Intelligent Systems

Table of Contents

Toggle

Author:

Ammar Ahamed

Head of Growth Marketing, Kavida.ai

Ammar leads growth marketing efforts at Kavida, where he drives marketing strategy, demand generation, product positioning, public relations and go-to-market strategy.

Related articles

The ERP Migration Myth: How Agentic AI Unblocks Value Across Fragmented Systems

Procurement leaders today need more than just efficient workflows—they need insights that drive smart decision-making. For decision makers...

Cleaning and Consolidating Parts Data Across ERPs with AI Agents

Procurement leaders today need more than just efficient workflows—they need insights that drive smart decision-making. For decision makers...

AI Intimacy: How Supply Chain Agents Adapt to You

Procurement leaders today need more than just efficient workflows—they need insights that drive smart decision-making. For decision makers...